Welding Solution for Aluminium Ute Trays and Toolboxes

Our client, a manufacturer specialising in aluminium Ute trays and toolboxes, encountered challenges in welding thin aluminium components to ensure consistent, high-quality welds. The client sought a solution that would enable them to produce aluminium structures with impeccable weld quality and aesthetics while maintaining efficiency and productivity.

KEY CHALLENGES

- Welding Thin Aluminium Components: Welding thin aluminium sheets required precision and control to avoid warping or distortion while achieving strong, consistent welds.

- Consistent High-Quality Welds: The client needed welds with a TIG-like finish, characterised by smooth, aesthetically pleasing weld beads, to meet the expectations of their customers.

- Efficiency and Productivity: Balancing weld quality with efficiency and productivity was crucial to meet production demands and maintain competitiveness in the market.

To address the welding challenges faced by our client and achieve consistent, high-quality welds on aluminium Ute trays and toolboxes, our team proposed a tailored solution leveraging advanced robotic welding technology.

SOLUTION HIGHLIGHTS

Infinite Robotics Dual Station Headstock System: The dual station headstock system provided a stable platform for precise positioning and rotation of the aluminium components during welding. This ensured optimal access and visibility for the welding process, enhancing weld quality and consistency.

Fanuc ArcMate 120iD/12L Robot: Equipped with a Fronius CMT (Cold Metal Transfer) welding system, the Fanuc ArcMate 120iD/12L robot offered advanced capabilities for welding thin aluminium components with superior control and precision.

Perfect Harmony between Welder and Robot: Through skilled and experienced integration, our team achieved perfect synchronisation between the welder and the robotic system. This seamless integration allowed the customer to consistently produce high-quality welds efficiently, meeting the stringent requirements of aluminium Ute trays and toolboxes.

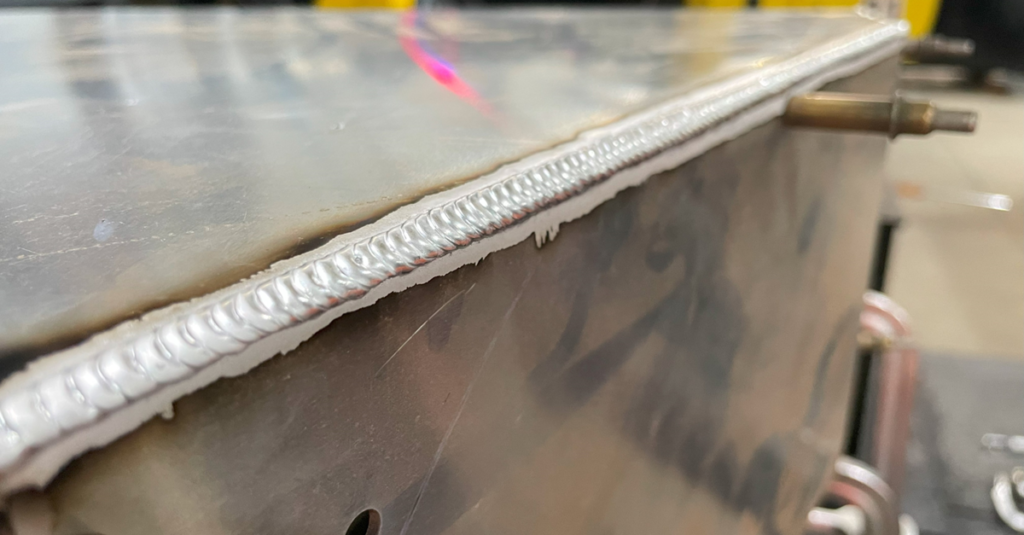

As welded with no clean up using a Fronius CMT Welding System

RESULTS

- Consistent High-Quality Welds: The implementation of the robotic welding solution enabled the client to achieve consistent, high-quality welds on thin aluminium components, meeting the TIG-like finish desired for Ute trays and toolboxes.

- Enhanced Efficiency and Productivity: By leveraging robotic automation, the client optimised their welding processes, reducing cycle times and maximising productivity while maintaining exceptional weld quality.

- Customer Satisfaction: The impeccable weld quality achieved with the robotic welding solution enhanced the overall aesthetics and durability of the aluminium structures, leading to increased customer satisfaction and loyalty.

Our tailored robotic welding solution provided our client in the aluminium ute tray and toolbox manufacturing industry with the capability to consistently produce high-quality welds efficiently and effectively. By combining advanced robotics technology with expertise and precision, we empowered our client to meet the demands of their customers while maintaining competitiveness in the market.