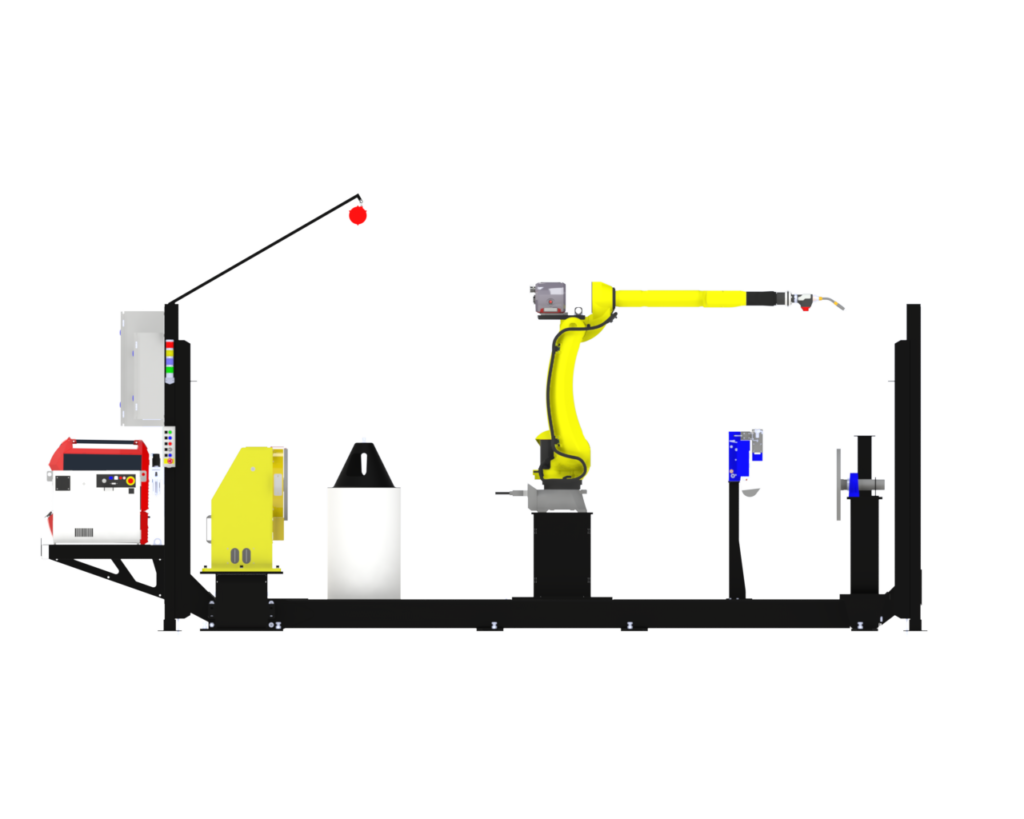

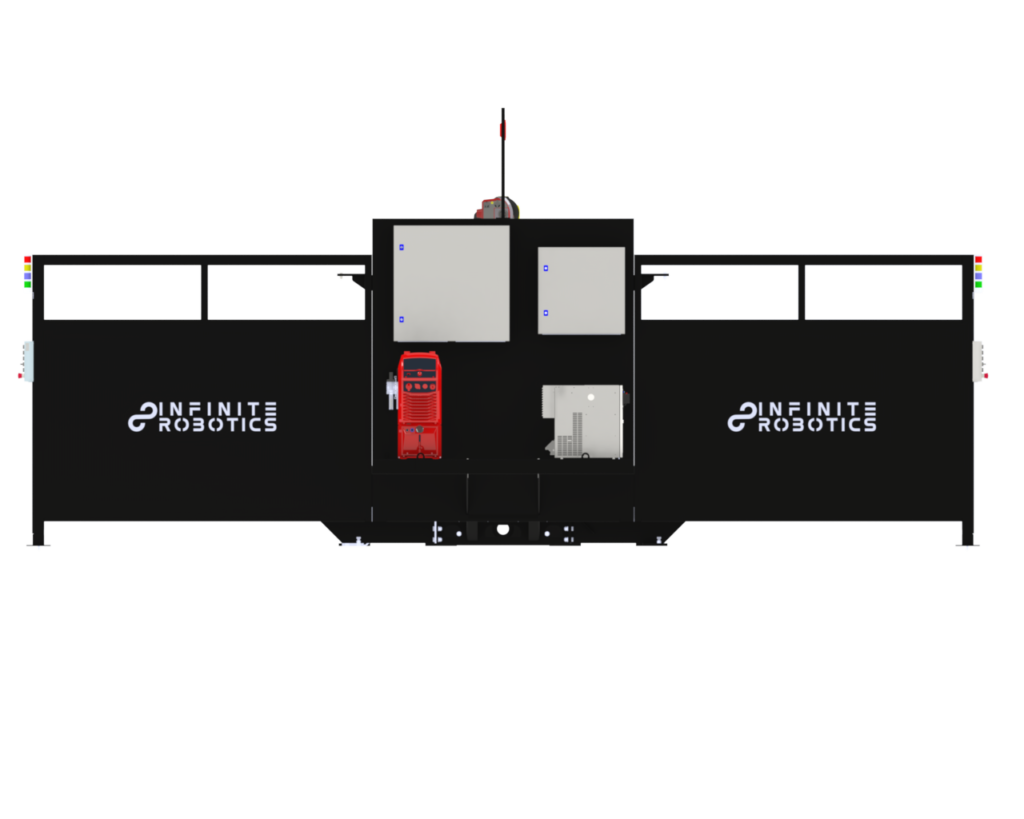

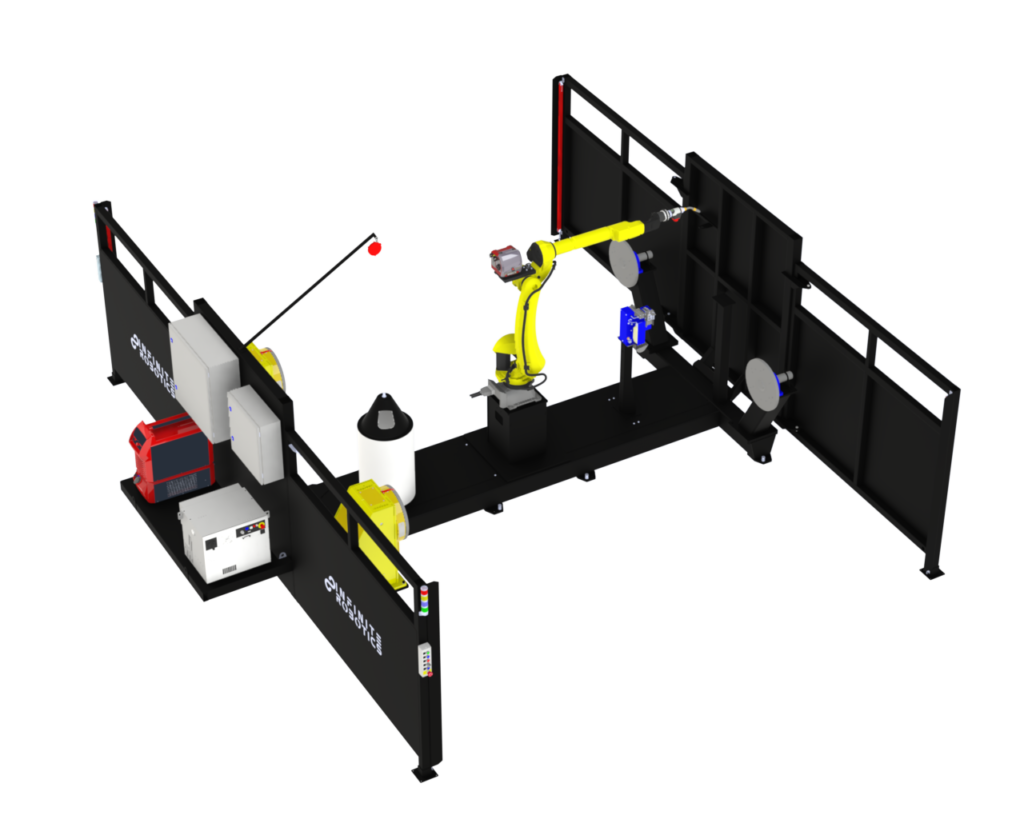

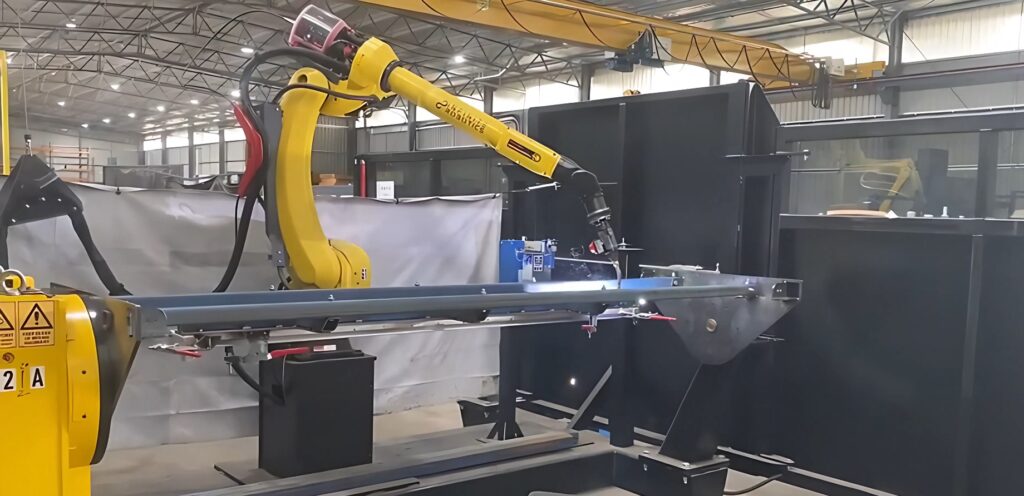

DUAL STATION

Pre-engineered flexible welding system

The Infinite Robotics Dual Station head and tailstock system offers a pre-engineered solution for swift and trouble-free implementation. It comes fully equipped with all the essentials needed to initiate welding straight away. The ingenious dual station design allows for simultaneous operation by both the operator and robot, significantly boosting productivity and enabling you to accomplish more welding tasks in less time.

| Programming Type | Teach pendant or off-line programming |

| Robot Reach | Up to 2272 mm |

| Welding Processes | GMAW, MCAW, FCAW, GTAW |

| Welding Power Source | Fronius or Kemppi water cooled |

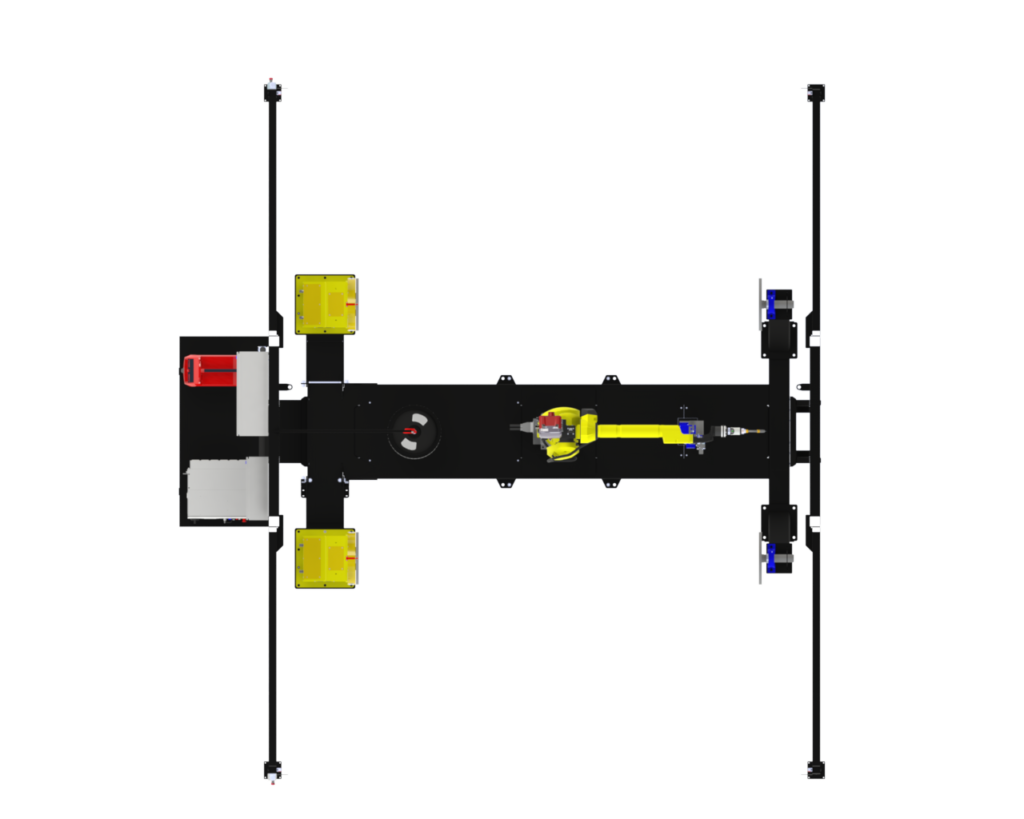

| Working Area | 3800 mm x 1500 mm |

| Welding Positioner Payload | 2000 kg |

PRODUCT HIGHLIGHTS

Proven modular design using leading brands means you get welding faster and stay welding longer.

Dual station design means that the robot can weld on one station while the operator loads/unloads on the other, increasing your production output.

The robot-controlled headstock allows you to rotate your parts to achieve optimal welding positions.

Features

- Fanuc ArcMate welding robot

- Pre-engineered modular design

- Onsite installation, commissioning and training

Advantages

- Precise, robust, and reliable industrial robot

- State of the art welding systems from leading global suppliers

- Dual station configuration

- Our training program ensures that the operators have the robot up and running fast

Benefits

- Proven design using the highest quality equipment to keep you welding day in and day out

- Expert inhouse technical support on the robot and welding system

- Conforms to the highest safety standards keeping your people safe

- Quick implementation